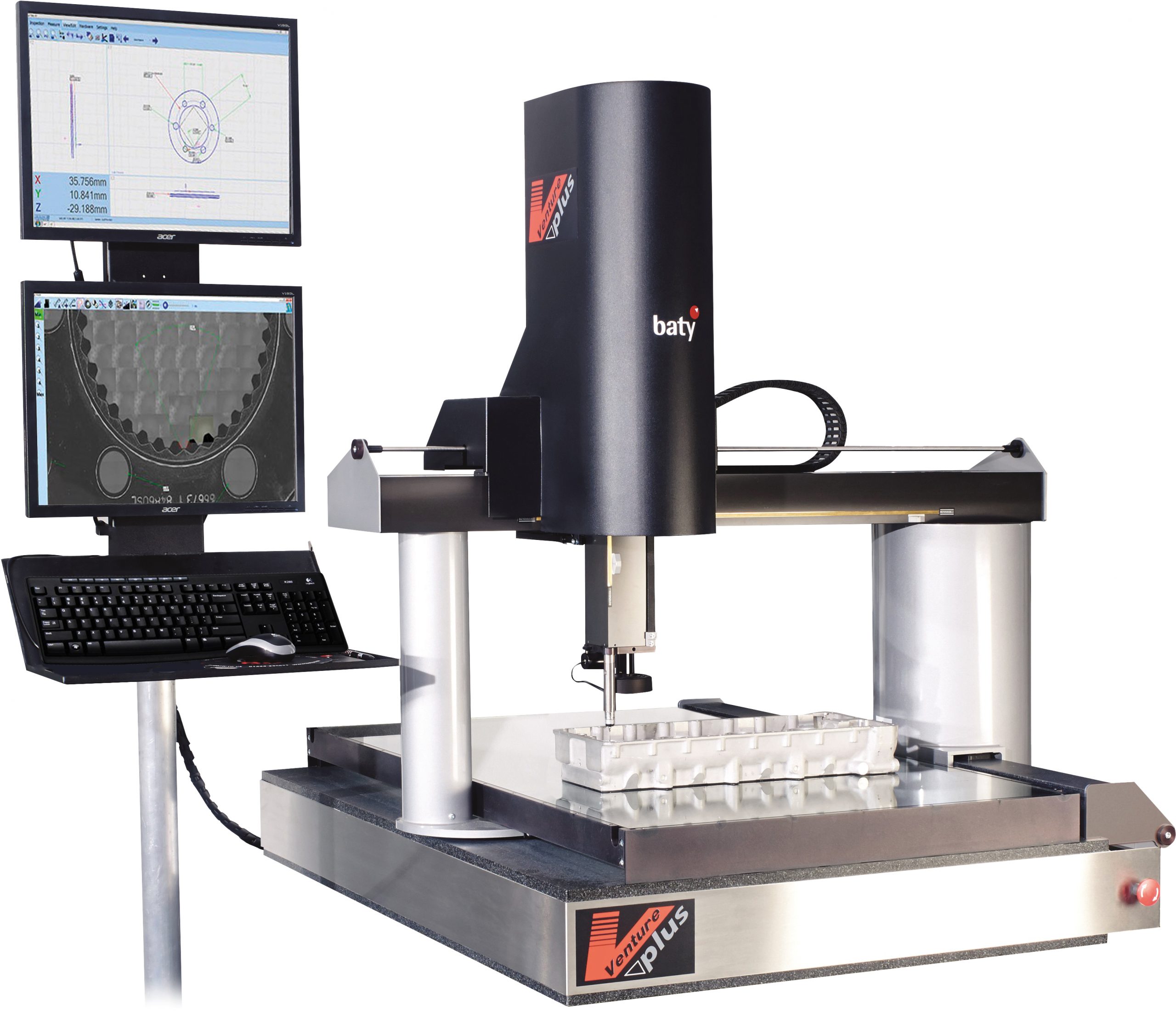

The bridge type construction is all aluminium resulting in low inertia and low thermal mass. Air bearings are used on all axes and a granite Y beam is used for increased accuracy. This ensures that the machine will expand and contract uniformly with temperature changes ensuring minimal distortion and subsequent errors. Ambient temperature can be compensated for within the Fusion software making Venture Plus ideal for use on the shop floor.

Complete with our standard zoom optics and programmable, segmented LED surface lighting, Venture Plus offers the same level of camera based functionality as every other Venture.

The use of a touch probe is optimised on a CNC system. Measurements from data points taken using the touch probe can be combined with those taken using Video Edge Detection for optimum speed and reduced inspection times.

A probe changer rack can be installed so that probe modules fitted with a variety of pre- calibrated styli can also be used in the same inspection. When a change of stylus is required, the system automatically puts the current probe module back in the rack and picks up the next to continue the inspection process. This functionality can be combined with our sophisticated Edge Detection to offer the ultimate in large format multi-sensing Vision systems – Venture Plus.

VP-6460-CNC with 640mm x 600mm x 250mm measuring range

VP-6490-CNC with 640mm x 900mm x 250mm measuring range

VP-100100-CNC with 1000mm x 1000mm x 400mm measuring range

VP-100150-CNC with 1000mm x 1500mm x 400mm measuring range