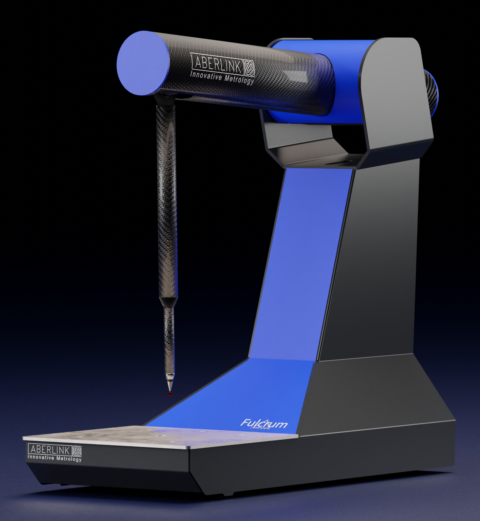

Fulcrum Manual CMM

The Fulcrum is a revolutionary manual CMM, by employing a three rotary axis design, Aberlink have created a compact and portable design enabling it to be used where it is needed, on the shop floor near your machine tools.

‘EXTOL’ SHOP FLOOR CNC CMM

True to Aberlink’s heritage for innovation, the Extol is the world’s first CMM to utilise a delta mechanism. Designed for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

HORIZON CNC CMM

The Horizon CMM breaks new ground in design and innovation using frictionless linear drives, which are the key to its fast and exceptionally smooth motion. The kinematic isolated drive structure is completely independent of the CMM structure and ensures that the motor thrust is directed through the centre of gravity of the moving parts. This not only avoids acceleration induced metrology errors but also has the effect of thermally isolating the motors from the metrology structure of the CMM.

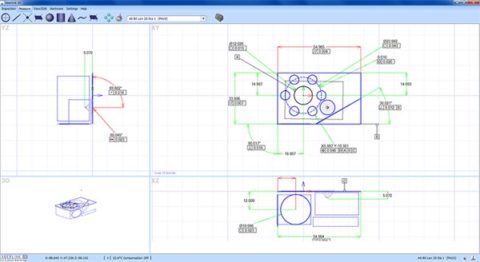

Aberlink 3D Measurement Software

Aberlink 3D software is not only ‘easy-to-use’, but also has the depth of functionality to make it the choice for either first time users or full-time inspection professionals. Aberlink CMM software updates will be available free of cost till machine life. Software suitable for coordinate measuring machines with either touch, scanning or vision systems.

Azimuth CNC Coordinate Measuring Machine

The revolutionary bridge of the Azimuth coordinate measuring machine incorporates aluminium honeycomb sheets developed for use in formula one and the aerospace industry. The remarkable stiffness to weight ratio that this provides gives the Azimuth an edge in both performance and speed. For a machine of this size, the Azimuth is not only fast, but extremely accurate.

Zenith 3 CNC CMM – ( CMM Machine )

Zenith 3 coordinate measuring machine is the perfect affordable metrology solution for big and heavy parts. Making large scale CMM measurements not only simple, but affordable.

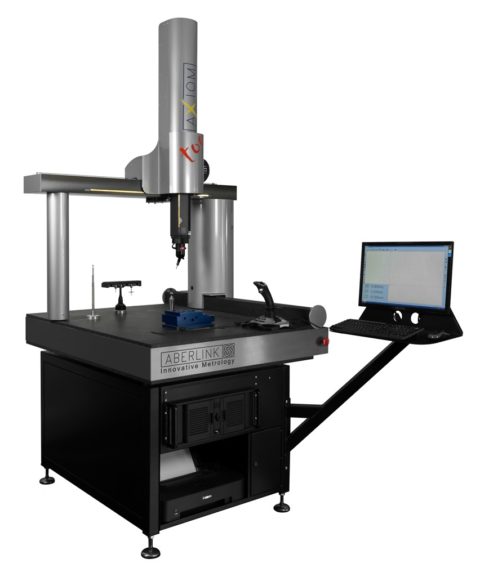

Axiom too CNC CMM – High Specification

Fast and accurate coordinate measuring machine with drive rod technology which allows even greater accelerations to be achieved. The HS model measures approximately 20% quicker than the standard variant – ideal for high volume measurement.

Axiom too CMM – Manual & CNC

Coordinate measuring machine available as either a manual machine or with full CNC control. An unique feature of the Axiom too is that manual machines can be simply upgraded to CNC at any point in the future.

- 1

- 2