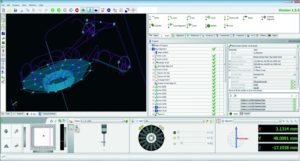

With non-contact vision measuring machine, the measurements in 2D and/or 3D are performed without the risk of product deformation or damage. To overcome the physical limitations of non-contact measurement the DeMeet multi-sensor machines can be additionally equipped with a touch probe system.

Baker has collaborated with Schut Geometrical Metrology to present 3D CNC Coordinate Measuring Machines manufactured in the Netherlands with Video Measurement (Optical) & Touch Probe Measurement facility depending upon the customer’s requirements & are available in 5 measuring range models.

With an excellent price-performance ratio, the DeMeet measuring machines break the barrier for high precision quality control on the production floor as well as in measuring laboratories.

Applications of the Video & Multi-Sensor measuring are among others in the Precision Engineering, Medical, Plastics and Electronics industry.

| DeMeet-220 | DeMeet-400 | DeMeet-404 | DeMeet-443 | DeMeet-705 | |

|---|---|---|---|---|---|

| Measuring range (mm) | X = 220, Y = 150, Z = 200 | X = 400, Y = 250, Z = 200 | X = 400, Y = 400, Z = 200 | X = 400, Y = 400, Z = 300 | X = 700, Y = 500, Z = 300 |

| Table size (mm) | X = 357, Y = 260 | X = 560, Y = 422 | X = 560, Y = 574 | X = 560, Y = 574 | X = 930, Y = 700 |

| Dimensions (mm) | W = 455, L = 725, H = 615 | W = 870, L = 930, H = 1570 | W = 870, L = 1245, H = 1580 | W = 870, L = 1245, H = 1800 | W = 1534, L = 1550, H = 1830 |

| Weight (approx. kg) | 110 | 510 | 710 | 730 | 1400 |

| Maximum load (kg) | 20 | 50 | 50 | 50 | 60 |

| Technical Specifications General Specifications | Video Model | Combo Model |

|---|---|---|

| Video System | DeMeet Camera (1/2" Sony-CCD) | |

| Touch Probe System | -------- | Renishaw TP20-5W (Standard) |

| Nikon Telecentric Lenses | 3.0x (1.0x, 5.0x and 10.0x optional) | |

| Leica design Telecentric Lenses | 2.0x (1.0x, 5.0x and 10.0x optional) | |

| Ringlight* | White LED: 3 Rings, 16 Segments and 48 Cell (adjustable) | |

| Backlight and Coaxial Light | Adjustable | |

| Reference sphere (mm) | -------- | Ceramic Ø 25 |

| Work table | Anodized aluminum, tention relived. Mounting hole pattern prepared for DF-system | |

| Drive Equipment | DC Servo Motors | |

| Operation | Motorized joystick control / Full CNC control | |

| Construction (DeMeet-220) | Cast iron, extremely tention relieved | |

| Construction, (Other Models) | Granite Surface Plate (DIN876/00) Portal: cast iron, extremely tention relieved | |

| *For video models (not for DeMeet-220) a Ring light with 4 rings,16 segments and 64 cells can be supplied as an option. | ||

| Measuring Specifications | ||

| Resolution ( µm) | 0.5 (0.1 optional) | |

| Accurancy in µm for 0.1µm model (L in mm) | U1(X,Y,Z) = 4+L/150* | |

| U2(XY) = 5+L/150 | U3(XYZ) = 5 + L/150* | |

| Accurancy in µm for 0.1µm model (L in mm) | U1(X,Y,Z) = 3+L/200* | |

| U2(XY) = 4+L/200 | U3(XYZ) = 4 + L/200* | |

| Max. Velocity DeMeet-220 (mm/s) | X, Y = 200, Z = 50 | |

| Max. Velocity DeMeet (mm/s) | X, Y = 250, Z = 50 | |

| *The acuuracy of the probing system should be taken account. |