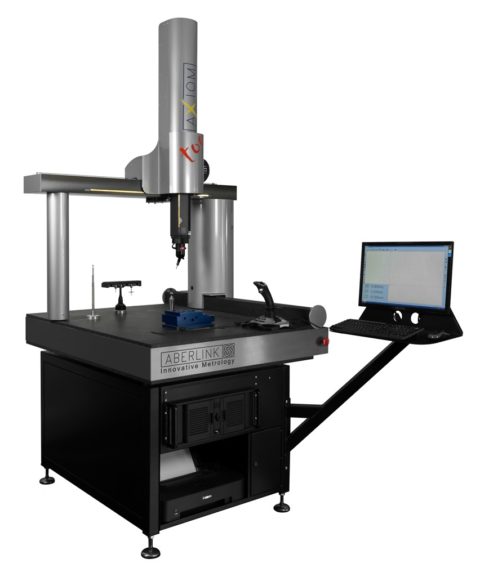

Coordinate measuring machine available as either a manual machine or with full CNC control. An unique feature of the Axiom too is that manual machines can be simply upgraded to CNC at any point in the future.

Fast, accurate and reliable, the Axiom too CMM comes in four different sizes with Y axis travel up to 1500mm. Available as either a manual machine or with full CNC control, the Axiom too can be used with touch trigger probe, continuous contact scanning probe or with Aberlink’s revolutionary non-contact camera system.

The all aluminium bridge structure not only ensures that the Axiom too has low inertia and hence high acceleration to get the job done quickly, but also that the temperature of the machine rapidly follows the temperature of the room, ideal when the CMM is not housed in a controlled environment. Temperature compensation in the software reports results as if they had been measured at 20°C. The standard high-tech granite and aluminium table, originally developed for the optics industry, provides fantastic natural damping of high frequency vibration and the granite Y rail allows pre-loading of the bridge air bearings in both directions for superior accuracy.

Another unique feature of the Axiom too is that manual machines can be simply upgraded to CNC at any point in the future, which is great if you are not initially sure of your requirement or perhaps can’t initially justify the additional cost of a CNC machine. Because of Aberlink’s fully integrated manufacturing processes, the Axiom too offers unbelievable value, but above all it is simple to use. Aberlink 3D measurement software is way out on its own as the market leader for ease-of-use, perfect for both occasional user and also metrology professional alike.

Key Features

- Shortest learning curve of any equivalent system

- Smallest overall footprint of any comparable size CMM

- Choice of Y axis sizes ranging from 600mm to 1500mm

- Suitable for the workshop environment

- Protection from environmental vibrations as standard

- Optimized friction free air bearings, all aluminium bridge and granite table

| Axis Travel (mm) | Overall Size (mm) |

|---|---|

| X 640 Y 600, 900, 1200, 1500 Z 500 | X 1130 Y 900, 1200, 1500, 1800 Z 2320 |

| *Volumetric Accuracy: | TP20 (2.4 + 0.4L/100) μm TP200 (2.3 + 0.4L/100) μm SP25M (2.1 + 0.4L/100) μm |

| Scale Resolution: | 0.5μm |

| **Optimum Temp Range: | 18 - 22°C |

| Operational Temp Range: | 0 - 45°C |

| Table: | Honeycomb aluminium & granite or solid granite |

| Table Load Capacity: | 300kg (Honeycomb) or 500kg (Solid) |

| Max. Velocity Vector: | 600mm/sec (CNC) |

| Max. Acceleration Vector: | 600mm/sec² (CNC) |

| Air Consumption: | 50 l/min (1.8 cfm) |

| Required Air Pressure: | 4 bar (60 psi) |

**Installation environment thermal limits: Rate of change <1°C/hr and <2°C/24hr. Temperature gradient <1°C/m

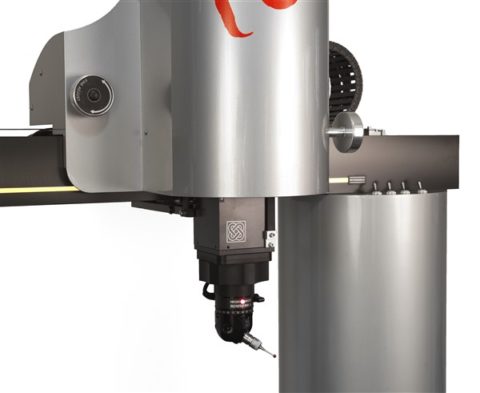

| Common Probe Options (Renishaw): | Machine Options: |

|---|---|

| • MH20i • RTP20 • PH10T (w/TP20, TP200) • PH20 • PH10M (w/SP25) • PH6M (w/SP25) | • Automatic Temperature Compensation • Touch Screen Joystick • CCD Camera System • Collimated Back Light Option |